Design & Engineering in the context of an Original Design Manufacturer (ODM) encompasses the design and development of state-of-the-art electronic products and solutions. From conception to series production, both design and engineering play a crucial role in ensuring excellent quality, functionality and reliability.

At Lacon, we pride ourselves on employing high-tech hardware and software experts in Design & Engineering. Our experienced team of engineers, developers and designers work closely with you to develop customised solutions that meet your individual requirements. We utilise the latest technologies and proven processes to deliver first-class products.

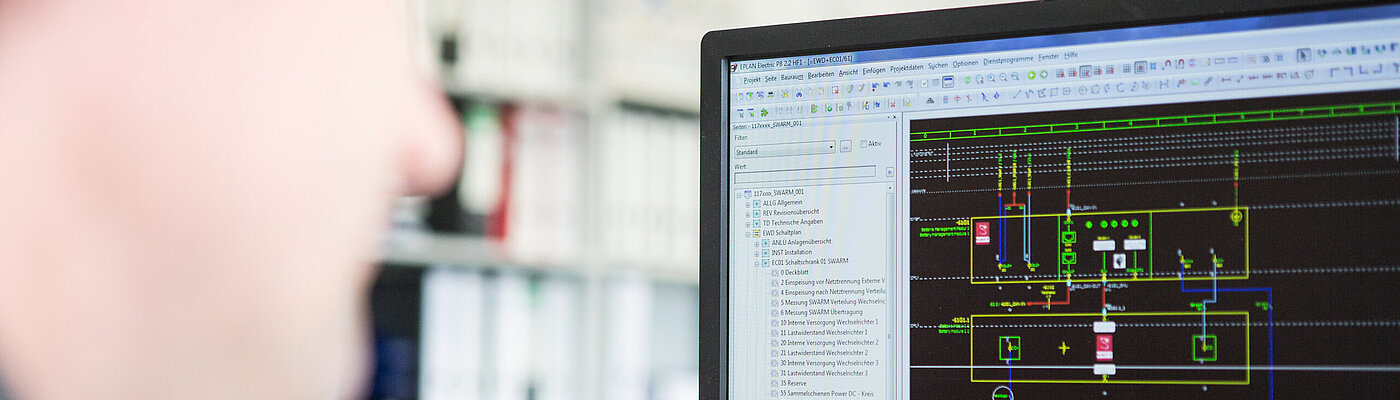

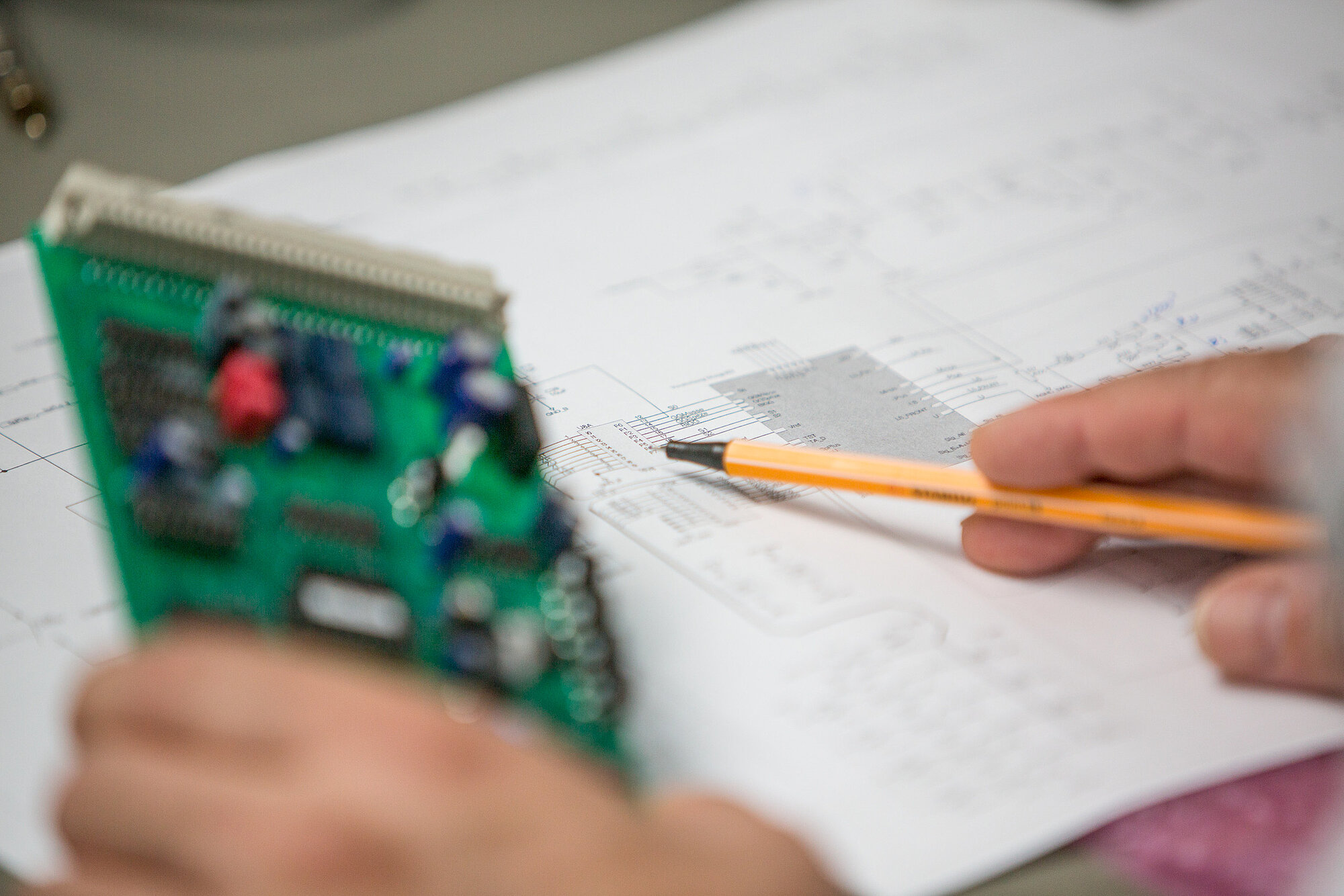

Our design process begins with a thorough analysis of our customers' requirements and objectives. We take into account aspects such as product life cycle, functionality, reliability, cost optimisation and design aesthetics. By using state-of-the-art software and simulation techniques, we guarantee the best possible performance and efficiency of our designs.

We work closely with our customers to develop prototypes and carry out extensive testing to ensure that all requirements are met. Our aim is to deliver innovative and market-ready solutions that meet the highest quality standards.

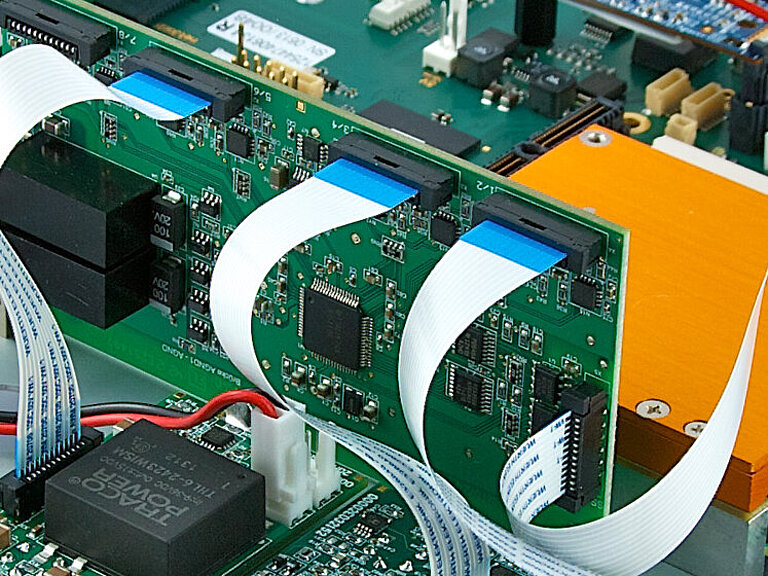

We offer a wide range of engineering services, including circuit development, PCB layout, system integration and product validation. Our experienced engineering team has in-depth expertise in various areas, including electronics design, embedded systems, software development and Internet of Things (IoT).

We are strongly positioned in power electronics and penetrate an industrial product from A-Z. We rely on agile processes to respond flexibly to your customer needs and deliver high-quality results in a timely manner.

As an ODM, we focus on the highest quality standards and are of course DIN EN ISO 9001+14001 certified. The medical technology standard 13485 is also fully covered.

Continuous innovation in our software, internal training and high process stability lead to the best customer satisfaction.

Our modern production facilities and our commitment to first-class technologies enable us to manufacture high-quality electronic products that truly deserve the Made in Germany label.

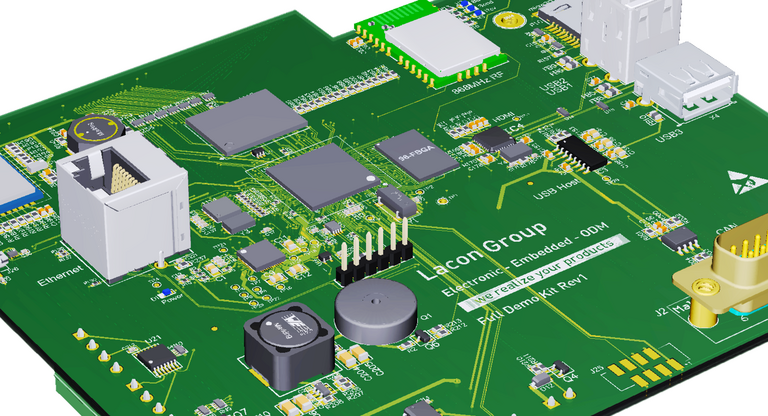

Our Design & Engineering portfolio covers embedded IoT developments, embedded platforms with single board computing solutions and industrial applications.

We offer customised solutions for various industries and markets, including automotive, medical technology and more. With our many years of experience and technological expertise, we are able to realise challenging projects and deliver innovative solutions.

When developing an innovative idea or a pioneering concept, it is essential to work with experts who have the experience, expertise and technological resources.

As a leading provider of electronics manufacturing services, we are your reliable partner in every step of the process - from idea generation to design and prototype development through to mass production.

Our many years of collaboration with renowned customers from various industries speak for our expertise and reliability. You provide us with the idea and experience the development of a fully industrialised product with us.

Our quality promise

Security with certificate

We emphasise compliance with international standards and norms at every step of the design and development process.

From the concept phase through to series production, we work closely with you to ensure that your products meet the highest quality standards, e.g.

- DIN EN ISO 9001 + 14001 + 45001

- Medical technology EN 13485

- Railway technology IPC A 610 und B 620

- Automotive IATF 16949

Hardware electronics

- Microcontroller programming 8, 16, 32 bit processors, e.g. STM, Texas Instruments, Renesas, Microchip

- Field-Programmable Gate Arrays Intel

- TFT display programming

- Embedded boards Q7, COM Express

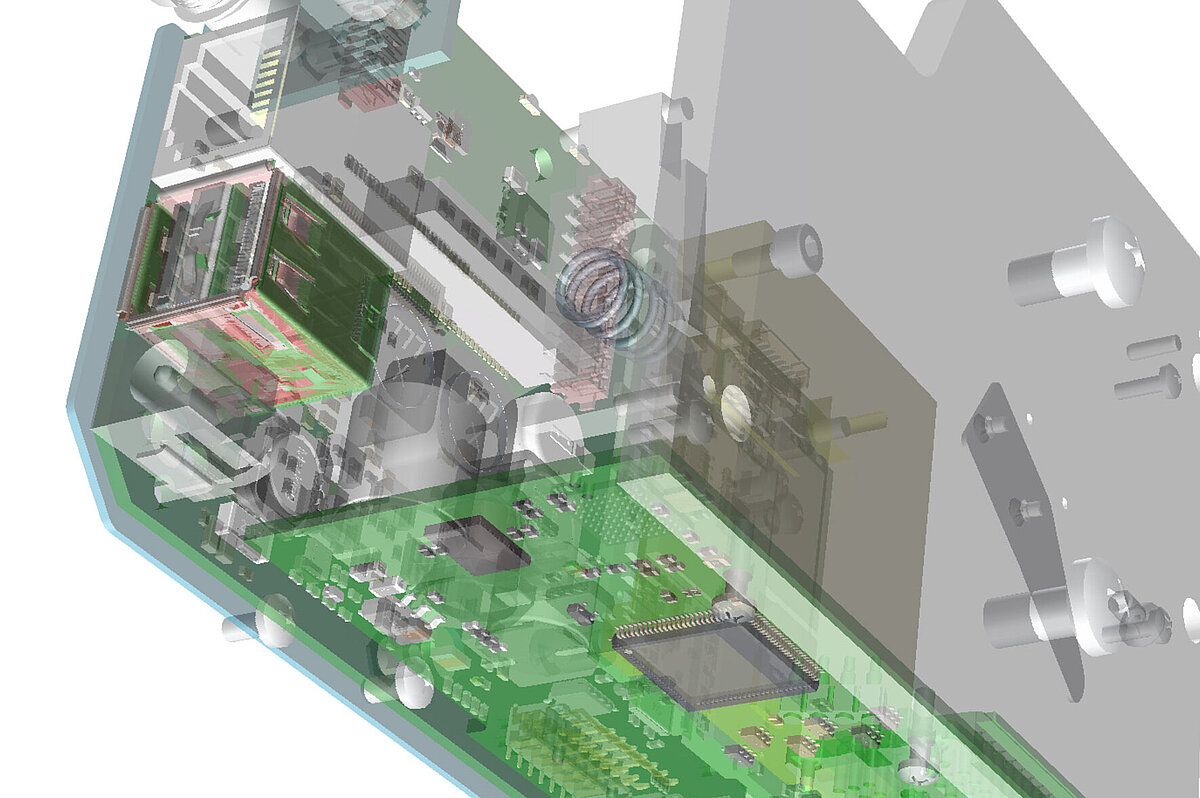

Embedded systems are specialised computer systems that are integrated into other products or systems to perform specific functions or control processes. These systems play a critical role in numerous industries, including automotive, medical, industrial automation and more. They also provide an efficient and reliable solution for complex requirements by seamlessly integrating hardware, software and firmware.

The Internet of Things (IoT) has created a number of interesting opportunities for industry to increase efficiency, reduce costs and improve competitiveness. Here are some reasons why the IoT is particularly interesting for industry:

- Data-based decision making: The IoT enables the collection of data in real time. By analysing this data, companies can make informed decisions, optimise processes and realise efficiency gains.

- Predictive maintenance: IoT-enabled sensors on machines and systems enable continuous monitoring of their condition. Based on this data, companies can implement predictive maintenance methods to minimise unplanned downtime and extend the service life of systems.

- Increased efficiency: By networking machines and devices, companies can optimise their production processes. Automation, more precise control and real-time adjustment help to utilise resources more efficiently.

- Supply chain optimisation: IoT enables better tracking and monitoring of goods in the supply chain. This improves transparency, enables more accurate inventory management and reduces losses and waste.

- Quality control: With IoT, companies can monitor the production process more closely and carry out quality checks in real time. This leads to a reduction in faulty products and improves overall quality.

- Energy efficiency: By implementing IoT in industrial plants, companies can better monitor and control their energy consumption. This helps to lower operating costs and reduce the environmental footprint.

- Innovation potential: The networking of devices opens up new opportunities for innovative products and services. Companies can develop new business models based on the utilisation of IoT data.

- Safety and compliance: IoT can help to improve the safety of plants and working environments. Real-time monitoring and early warnings help to prevent accidents. IoT solutions can also help to better fulfil safety standards and compliance requirements.

Overall, the Internet of Things offers a wide range of opportunities to increase operational efficiency, reduce costs and strengthen the industry's competitiveness.

An embedded platform offers various advantages, especially with regard to specialised applications and systems. Here are some of the most important advantages:

- Compactness and space saving: embedded platforms are designed to operate on a single board or in a small form factor. This enables a high level of integration of hardware components and saves physical space, which is particularly beneficial in applications with limited space.

- Energy efficiency: Embedded platforms can be optimised for specific tasks and functions, resulting in efficient energy consumption. This is particularly important for battery-powered devices, IoT applications or in environments where energy consumption is limited.

- High reliability and stability: As embedded platforms are developed for specific applications, they can be optimised for stability and reliability. This is particularly important in critical applications such as medical technology, industrial automation or aerospace.

- Specific function optimisation: Embedded platforms can be optimised for specific functions or tasks. This enables efficient execution of specialised applications without the unnecessary complexity of general purpose platforms.

- Fast response time: By being dedicated to specific tasks, embedded platforms can offer fast response times. This is particularly important in real-time applications such as industrial process control or automotive systems.

- Cost efficiency: Embedded platforms can be more cost efficient than more general purpose systems as they are tailored to specific requirements and do not include unnecessary functions.

- Security: The security of embedded platforms can be improved by reducing unnecessary functions and using specialised hardware. This is particularly important in applications that need to fulfil high security standards.

- Easy integration: Embedded platforms are often easy to integrate into existing systems as they are designed with clear functions and interfaces. This simplifies the development and integration processes.

These advantages make embedded platforms particularly suitable for applications in areas such as the Internet of Things (IoT), industrial automation, medical technology, automotive technology and many other specialised sectors.

A D&E (Design & Engineering) project typically comprises the following steps:

- Project definition: Determination of objectives, scope and requirements.

- Concept development: Collection of ideas, evaluation and selection of the best concept.

- Design phase: Detailed elaboration, technical drawings, material selection.

- Prototype construction: Production and testing of a prototype.

- Technical documentation: Preparation of instructions and specifications.

- Procurement and production: Material procurement, production planning and realisation.

- Commissioning: Installation, training and on-site testing.

- Handover and support: Customer support, maintenance services.

- Project completion: Evaluation of success, learning process documentation, final report.