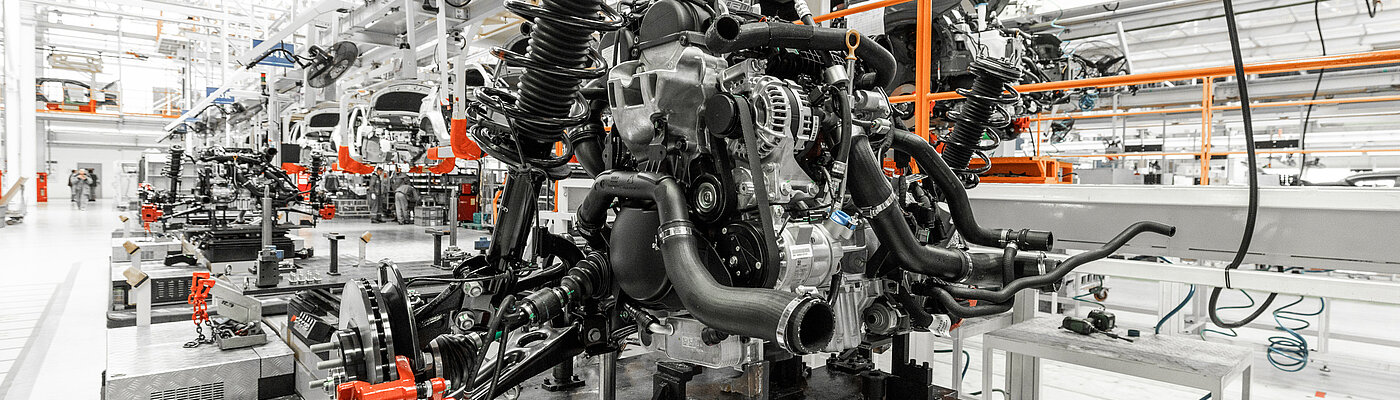

The modern mechanical engineering industry is facing ever-increasing challenges to develop high-quality products in ever shorter timeframes and bring them to market at competitive prices. In this context, cooperation with experienced and efficient partners plays a decisive role in order to be able to concentrate on one's core competences. One such partner is Lacon Electronic, one of the leading Top20 EMS companies (Electronic Manufacturing Services) and Original Design Manufacturer (ODM) in Europe.

Lacon Electronic has established itself as a long-standing partner for machine manufacturers and component suppliers by offering a wide range of services and products that span the entire product life cycle.

Whether it's consulting, idea generation, engineering, production capacity and manufacturing expertise, procurement management or after-sales services, Lacon is characterised by its commitment to innovation, quality and reliability.

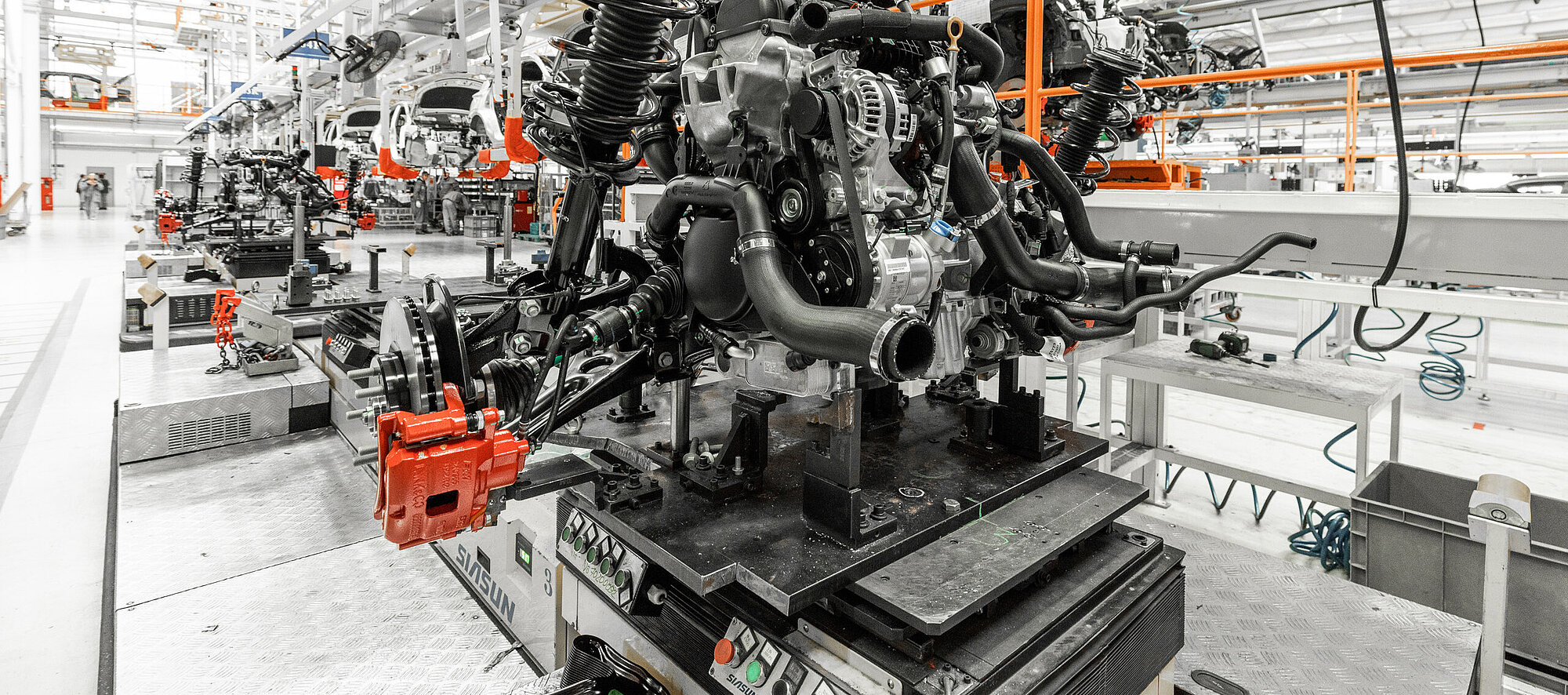

To ensure that your machines run reliably, you need reliable power transmission. That's why we assemble customised cable solutions for you. We provide you with exactly what you need, from consultation and planning to production and installation on site: Individual strands or system cabling of the highest quality, from small quantities to large series. This is genuine original design manufacturing made in Germany.

Whether you need encoder cables for data and signal transmission or motor cables to supply power to your large motors: We manufacture complete system solutions as well as customised special solutions for driving your machines. Naturally in the best Lacon quality and DESINA®, CE and RoHS-compliant, so that your cables can withstand all environmental and utilisation conditions.

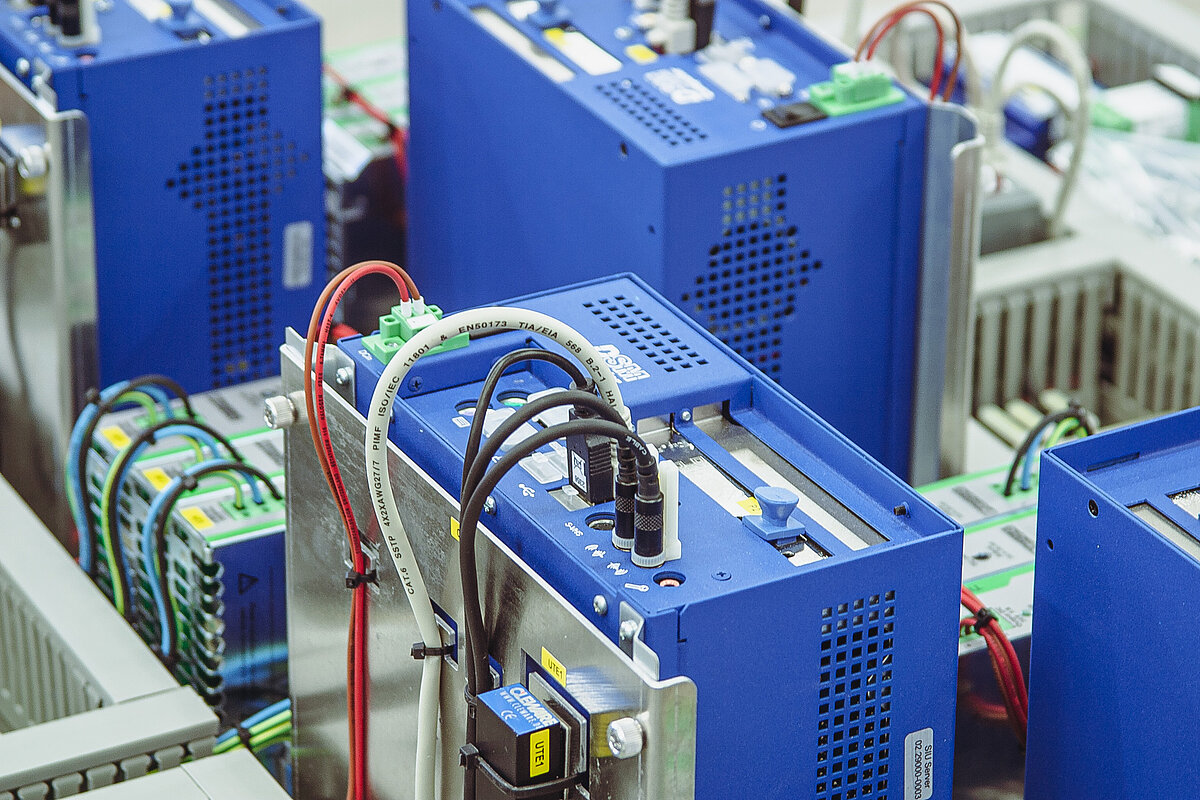

When it comes to housing electronic components, we are your specialist with in-depth expertise. Thanks to 30 years of experience in high-level switch cabinet construction, we plan and manufacture efficient switch cabinets, mounting plates and plug-in units for all applications. Naturally customised to your specifications and according to the requirements of your machine automation.

Our solutions for switch cabinet construction

- Initial sample construction and series production with integrated procurement

- Low-voltage control cabinets (<1,000V): Mounting plates, power distribution boards, converter cabinets, plug-in units, measuring cabinets, 19-inch plug-in units and much more.

- Continuity testing, high-voltage testing, series: Test adaptation with test certificate

- Electrical planning on EPlanP8

- CNC enclosure machining

- Small and medium quantities

- Assembly and commissioning at your site

Our products stand for quality "made in Germany". We set standards instead of just following them. Our industrial quality management system ensures that our products meet or even exceed all requirements. We take all current standards into account so that we can qualify your products for worldwide export.

In mechanical engineering, motor and encoder cables refer to specialised cables and wires used to transmit power and signals in machines. Motor cables transmit power from the power source to electric motors, while encoder cables are used to transmit signal information from sensors or encoders to control systems or other devices. These cables are crucial for the operation of machines as they ensure the power supply and the transfer of information between different components.

Cable carrier systems are mechanical devices that are used to guide cables and lines safely along a defined path while machines are in motion. They consist of a chain containing links in which the cables are protected and guided. These systems make it possible to protect cables and lines from damage caused by movement and environmental conditions and ensure a reliable supply of energy and information in automated machines and systems.

Switch cabinets are enclosures or cabinets that house electrical circuits, control components and other electronic devices. They are used to protect these components from external influences such as dust, moisture and mechanical damage. Control cabinets are often modular and allow for a structured arrangement of switching devices as well as easy maintenance and accessibility for maintenance work. These enclosures are crucial for the safety and efficiency of electrical control systems in industrial applications.