In the dynamic world of the electronics industry, life cycle management and obsolescence management play a crucial role in maximizing the lifespan of products and minimizing the impact of product obsolescence. These two concepts are closely linked and aim to ensure the efficiency, profitability and sustainability of products throughout their life cycle. Life cycle management (LCM) refers to the holistic view of a product from its conception to its disposal. Obsolescence management, on the other hand, focuses on minimizing the effects of product obsolescence.

The aim of obsolescence management is to ensure that a continuous supply of spare parts is guaranteed throughout the entire service life of industrial plants. It aims to respond to product discontinuations in good time and to develop strategic measures to cope with technological progress. These strategies are intended to ensure that the manufacture, operation and maintenance of machines and systems are guaranteed in the long term.

Regular medical check-ups often prolong the lives of responsible patients who undergo them voluntarily. The same applies to electronic assemblies.

Continuous and proactive health monitoring

- Continuous monitoring for defined assemblies

- Screening of components with regard to long-term availability

- Recommendations for stockpiling or substitution

- Detailed status reporting

Component database

We work with the Part Search tool, a product of Siliconexpert Technologies.

Founded in 2000, Siliconexpert provides accurate data on over 300 million electronic components from the global electronics industry.

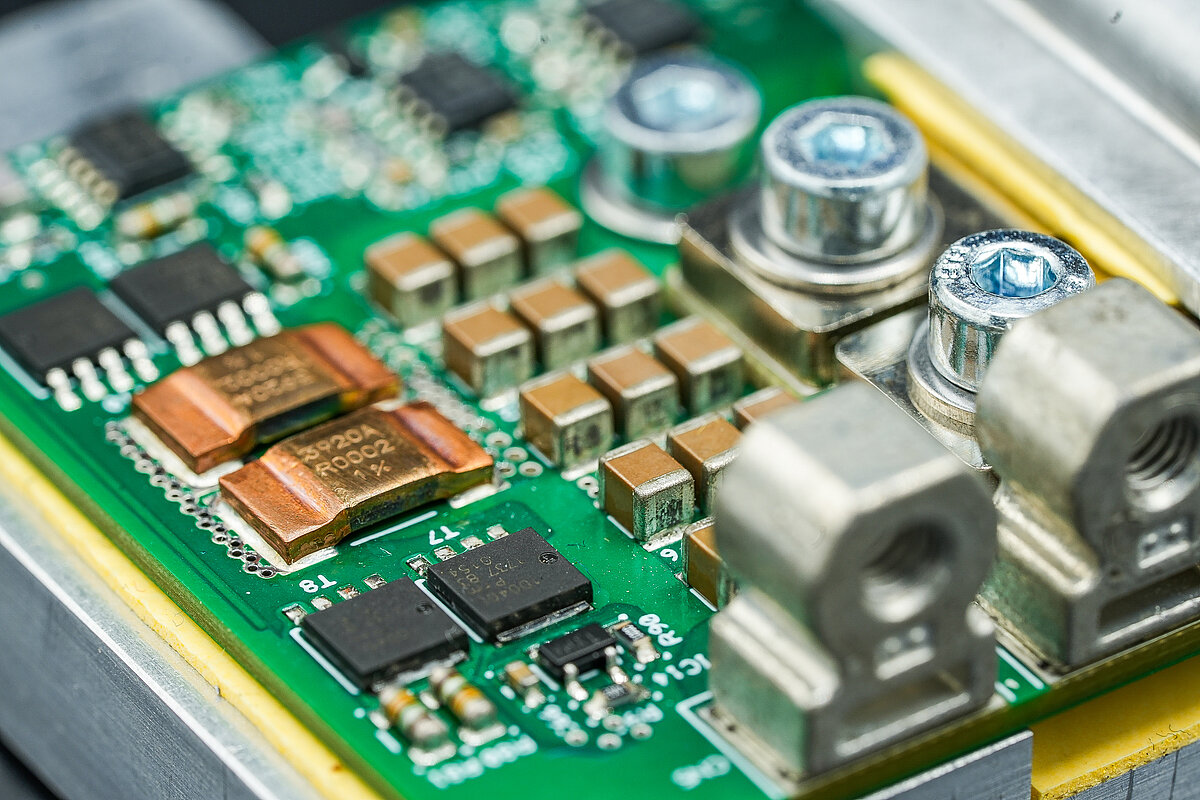

Lacon Reverse Engineering includes all services that make an existing, obsolete or discontinued electronic system producible again using the latest technologies.

Assemblies are analyzed and their structure, components, states and behaviours are extracted. A mostly intensive research phase is followed by a restructuring of the updated components.

Reverse engineering of assemblies

- Functional sample required

- Collection of all available documents

- Assembly including all available peripherals

- Test adaptations and programs

- Creation of original parts lists

- Functionally compatible redesign or replacement of obsolete components

- Re-creation of design files, parts lists and Gerber data

Reverse engineering or new development?

We will show you the options for deciding between efficient reverse engineering or new development.

One factor here is the functional share of embedded software in the overall system. Under certain circumstances, a completely new development may also be the more sensible option.

For expensive small series or assemblies with obsolete components and in the event of unexpected field failures, series repair is often a sensible alternative to new production.

Professional repair

In addition to all work on circuit boards using a wide range of technologies, we test and repair all types of industrial electronic devices.

Troubleshooting/ effort estimation

- Root cause determination, transmission of the cost estimate

- Fault rectification through repair or technical improvement

- Decision on repair, scrapping or component recycling for series repairs

Checking/testing the repaired assembly

- Usual warranties on the repairs

- Selection of the necessary test equipment

- High-quality adaptations for complete functional tests

Life cycle signals refer to information and notifications that occur during the life cycle of a product or component. These signals are crucial in order to be able to react to changes or developments in connection with a product at an early stage. In the field of supply chain management, especially in the electronics industry, life cycle signals include information such as end-of-life (EOL) announcements, product change notifications (PCN), and other relevant data concerning the life cycle and availability of products. Early knowledge of such signals enables companies to develop alternative procurement strategies in good time, avoid bottlenecks and ensure a smooth supply chain.

End-of-Life (EOL) announcements refer to the official notification from a manufacturer that a particular product or product line is at the end of its life cycle and will soon no longer be available. This can be for a variety of reasons, such as obsolete technology, lack of demand, component availability or regulatory requirements.

End-of-life announcements are important to give customers and business partners enough time to prepare for the end of product availability. This may involve customers replenishing their stocks, finding alternative products or updating their systems to be compatible with new products or technologies.

Product Change Notifications (PCNs) are notices issued by manufacturers of electronic components or products to inform customers of planned changes to their products. These changes can concern various aspects, including Design changes, material changes, manufacturing process changes, packaging changes or end-of-life information. PCNs are important to give customers time to prepare for upcoming changes and to ensure that their systems or products are not unexpectedly affected.